Browse by Category

View our products by vehicle service categories

View our products by vehicle service categories

Find us in person at these upcoming events

Learn about who we are, where we came from, and where we're heading

If a new product idea has the gears in your head turning, submit it to us and get paid if it gets made!

Installs crankshaft seal Services Ford Super Duty F-250, F-350, F-450, F-550, F-650 & F750 from 2011, 2012, 2013, 2014, 2015, 2016, 2017, 2018...

View full detailsServices Ford Super Duty F-250, F-350, F-450, F-550, F-650 & F750 from 2011-2019 For Rear Remover - See CTA 7315 Compare to Ford Factory Tool ...

View full detailsKit provides tools required to remove and install all crankshaft seals on a 6.7L Power Stroke engines Services Ford Super Duty F-250, F-350, F-450...

View full detailsFull-range deep metric socket set Sizes 6mm to 21mm 120mm long Broached for extra-deep reach Provides access to recessed areas with extra long bol...

View full detailsServices Ford Super Duty F-250, F-350, F-450, F-550, F-650 & F750 from 2011, 2012, 2013, 2014, 2015, 2016, 2017, 2018 & 2019 Includes: 1 R...

View full detailsThis tool is designed to remove and install the hub nut on these axles, which is critical to maintaining the proper preload on the axle components...

View full detailsSet of EPR (5-sided) Torx Plus® profile sockets, from 6EPR to 32EPR Also referred to as Pentalobe sockets Manufactured from satin finish chrome va...

View full detailsUse for replacing worn or damaged manual transmission mount The vulcanized rubber mount separates from the housing causing an increase of NVH duri...

View full detailsComprehensive "Flip" socket set offering two hex sizes in one socket. Half metric sizes for the removal of inflated, warped and mangled chrome-ca...

View full detailsServices Ford Super Duty F-250, F-350, F-450, F-550, F-650 & F750 from 2011, 2012, 2013, 2014, 2015, 2016, 2017, 2018 & 2019 Compare to Fo...

View full detailsServices: 1.5L (EA211) & 2.0L (EA888) Gen.4 VAG engines Applications: 2020+ Adapter is held in place with O-ring grip Adapter Color: White O.D...

View full detailsIntroducing the CTA Short Sleeve Shirt, designed for DIYers, mechanics, and automotive enthusiasts. Our 100% cotton shirt is proudly made right her...

View full details4 Pc. Thread Restoring File Set Includes 3 Thread Files #8231, #8233 & #8235, plus 1 Universal Thread File #2299 Includes both Metric & SA...

View full detailsUse for Installation and removal of head bolts on Subaru flat boxer engines Services: 1999-2020 Subaru Baja, Forester, Impreza, Legacy, O...

View full detailsKit contains everything required to perform timing service on 4.6L, 5.4L and 6.8L Ford Triton engines This comprehensive kit includes the followin...

View full detailsUse for locking the cams and crankshaft when replacing the timing chain and cylinder head gasket on the Porsche second gen V6 twin turbo engines A...

View full detailsMilton M-Style Connector Fitting Use with 7043 Quick Coupler Allows use of CTA adapters with other pressure bleeding tanks Included in 3930 Brake ...

View full detailsBrake Bleeding Adapter Pro Series features all metal construction adapter Services Toyota & Lexus models I.D. = 42mm Adapter has a 90° swivel ...

View full detailsUsed for fast oil filling without spillage or waste Great for vehicles with internal baffles or shields which restrict traditional oil funnels Ser...

View full detailsServices 6.4L Power Stroke Injectors Spring loaded design allows for easy removal of connector 4 prong fork design maximizes surface area on injec...

View full details

CTA carries a wide range of professional tools to cover every aspect of complex aftermarket service

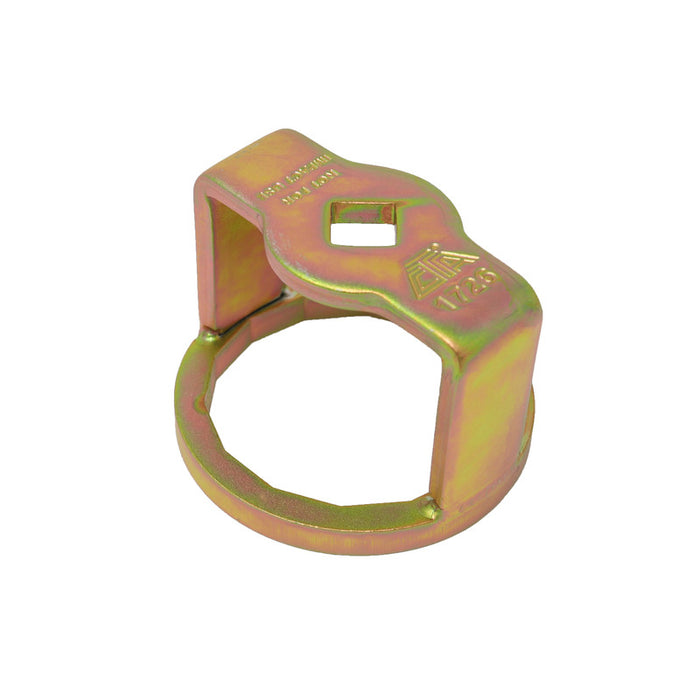

Extra Low-profile (21.15mm height) required for minimal clearance Services 6.7L Dodge RAM Cummins fuel filter canister (2010+) & RAM 3.0L EcoD...

View full details6-piece oil filter wrench set with secure magnetic stand Stand includes a magnetic bottom for secure placement on metal surfaces anywhere around t...

View full detailsRemove new, plastic oil drain plugs without damage Mates perfectly with oil drain plug Widened thumb-grip allows proper torque Applications: Acadi...

View full detailsServices: 1.5L (EA211) & 2.0L (EA888) Gen.4 VAG engines Applications: 2020+ Adapter is held in place with O-ring grip Adapter Color: White O.D...

View full detailsPrecision-stamped to remove Aftermarket and OE spin-on filters and filter housings 73mm x 14 Flute Interior Diameter 3/8” square drive Black fi...

View full detailsForged and machined from 6140 steel for removal of the most stubborn oil filter housing caps Services Toyota / Lexus 6 & 8 cylinder 64mm x 14...

View full detailsFor service of 10mm male square plugs 3/8" Square drive OD of 10mm end: 18.2mm OD of 3/8" sq. dr. end: 18.9mm OAL: 40mm Applications: BMW, Ford, ...

View full detailsServices: Transfer cases Engine oil pans, Manual transmission Differential drain plugs Fill plugs Size: 10mm Drive: 3/8" Essential for every ...

View full detailsServices: Transfer cases Engine oil pans Manual transmission Differential drain plugs Fill plugs Size: 8mm Drive: 3/8" Essential for every me...

View full detailsFeatures extra-thick yoke, expanding link mechanism, adjusting screw to tighten or loosen swivel and thick cushion grip Band Width: 25mm Size: 92-...

View full detailsInternal Male Insert O.D. = 56mm Adapter O.D. = 79.5mm Depth: 18mm Nitto fitting size: 1/2" / Threads: 1/8" BSP Included in 13pc. Master Cylind...

View full detailsCreates pressure to push brake fluid through the system 3 liter capacity tank with pressure release valve Filling hole with screw cap 0-70 PSI gau...

View full details7 Point socket for caliper retaining screws Applications: Audi Q7, S5 and various Mercedes Benz models 1/2" square drive OAL: 50mm Applications ...

View full detailsUse 7043 Quick Coupler adapter when you don’t have a Nitto designed quick connect Simply attach any 1/4″ BSP adapter to the 7043 adapter Now you a...

View full details10' Replacement Hose Assembly for 7015 Pressure Brake Bleeder Tank.

Milton M-Style Connector Fitting Use with 7043 Quick Coupler Allows use of CTA adapters with other pressure bleeding tanks Included in 3930 Brake ...

View full detailsSpecial design for injectors on small diesel engines 5 Point (Pentagon) Length: 36.85mm Chrome-vanadium construction for durability Broach depth:...

View full detailsApplications: Nissan, Mitsubishi, Subaru Included in 11pc. Master Cylinder Adapter Kit - CTA Part # 7300 Internal Male Insert O.D. = 34.5mm Adapte...

View full details12 Master Cylinder Adapters, plus 1 Quick Coupler, paired with #7015 Pressure Bleeder Tank will service most makes & models Kit includes the ...

View full detailsBrake Bleeding Adapter Pro Series features all metal construction adapter Services GM, Tesla Model 3 & Y I.D. = 37mm Adapter has a 90° swivel ...

View full detailsCLICK HERE TO VIEW PRO THREAD FLYER • Includes 10 inserts: 1.5D, 0.7500" • Use with CTA Kit #34089 PRO-THREAD FEATURES: • Pro-Thread Kits offe...

View full detailsCLICK HERE TO VIEW PRO THREAD FLYER Pro-Thread Kits offer a cost effective method of repairing and strengthening threads in various materials su...

View full detailsCLICK HERE TO VIEW PRO THREAD FLYER Pro-Thread Kits offer a cost effective method of repairing and strengthening threads in various material...

View full details• Includes 10 inserts: 1.5D, 9mm • Use with CTA Kit #35069 PRO-THREAD FEATURES: • Pro-Thread Kits offer a cost effective method of repairing and st...

View full detailsPro-Thread Kits offer a cost effective method of repairing and strengthening threads in various materials such as cast iron, steel, aluminum, ...

View full detailsAlloy steel tap cleans Oil Pan & other threads Size: 16mm x 1.50 Applications: Dodge, Jaguar

Alloy steel tap to clean Oil Pan & other threads Size: 12mm x 1.75 Applications: Ford, GM, GMC, Saturn

CLICK HERE TO VIEW PRO THREAD FLYER Repairs damage threads in spark plug ports For non-tapered seat ONLY Coiled inserts create a permanent and...

View full detailsCLICK HERE TO VIEW PRO THREAD FLYER • Includes 10 inserts: 1.5D, 15.0mm • Use with CTA Kit #37109 PRO-THREAD FEATURES: • Pro-Thread Kits offer...

View full detailsCLICK HERE TO VIEW PRO THREAD FLYER • Includes 10 inserts: 1.5D, 0.3750" • Use with CTA Kit #33049 PRO-THREAD FEATURES: • Pro-Thread Kits offe...

View full detailsHigh quality terminal disconnect tool eliminates damage to wires or terminal blocks Dim: Pitch 1.8mm Applications include, but not limited to: AM...

View full detailsFor the removal of VAG and Porsche connectors Connectors are found on MAF sensors, coil packs, headlights, fog lights, level sensors, map sensors,...

View full detailsHigh quality terminal disconnect tool eliminates damage to wires or terminal blocks Dim: 3.2mm x 2.0mm Applications include, but not limited to: ...

View full detailsKit provides the newest designed disconnect tools Manufactured using high quality steel Using the proper terminal disconnect tool eliminates dama...

View full detailsChecks for leaky, sticky, or burnt valves, incorrect timing, accurate fuel pump vacuum and pressure and gas line leakage Gauge is calibrated from ...

View full detailsHigh quality terminal disconnect tool eliminates damage to wires or terminal blocks Dim: 1.2mm x 0.6mm Applications include, but not limited to: ...

View full detailsHigh quality terminal disconnect tool eliminates damage to wires or terminal blocks Dim: ø 2.9mm Applications include, but not limited to: DEUTS...

View full detailsThe turbo system leakage tester helps locate air leaks in the components by plugging the output side of the turbo and plugging the intake inlet Ai...

View full detailsUsed to check voltage value on 6, 12 & 48V systems Full voltage measurement range: 4V - 60V Small testing current < 10mA Coil cord stre...

View full detailsHigh quality terminal disconnect tool eliminates damage to wires or terminal blocks Dim: 1.0mm x 1.0mm Applications include, but not limited to: ...

View full details

Installs crankshaft seal Services Ford Super Duty F-250, F-350, F-450, F-550, F-650 & F750 from 2011, 2012, 2013, 2014, 2015, 2016, 2017, 2018...

View full detailsDrill 2.5mm

Services Ford Super Duty F-250, F-350, F-450, F-550, F-650 & F750 from 2011-2019 For Rear Remover - See CTA 7315 Compare to Ford Factory Tool ...

View full detailsMilling Drill M10

Milling Drill M8

Kit provides tools required to remove and install all crankshaft seals on a 6.7L Power Stroke engines Services Ford Super Duty F-250, F-350, F-450...

View full detailsDescription: 10mm x 1/2" Square Drive w/ long shaft 12-Point wrench fit Toyota engine head bolts 10mm application include Toyota, Lexus & S...

View full detailsTiming set for Ford 2.0L & 2.3L EcoBoost engine Set includes: 2880X04 - T.D.C. Crank Timing Pin 1026L - Camshaft Alignment Tool 1804 - Crank...

View full detailsSet of Two Guides

Cam Phaser & Timing Chain Locking / Holding Set for 3.6L Pentastar engines Services 2016 and newer Chrysler, Dodge & Jeep models Compare t...

View full details